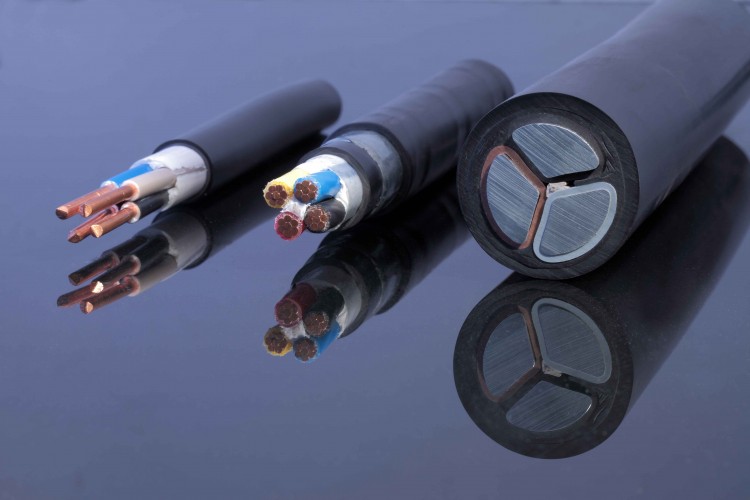

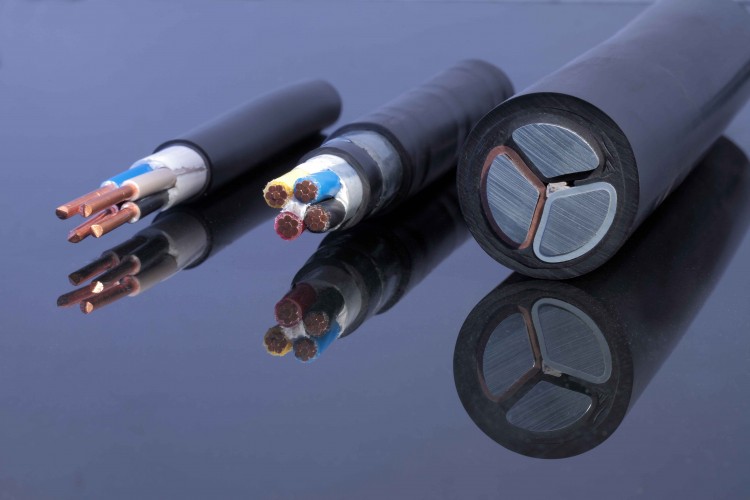

When you throw out any old cables, there are still a variety of useful materials, such as copper and lead, within them that can be recycled. To get to these metals the old cables go through a process called cable granulation. Read on to discover how your old cables are recycled.

Step 1. The cable is graded

Before the cable granulation process actually begins, the cable itself needs to be graded. Cable comes in a variety of thickness and can contain a number of components, the most popular being copper, lead and steel. It is important to grade the cable correctly so it can be processed in the correct way. The next step would then be either stripping or shredding. A quick tip would be to ensure that all cable is free from heavy plugs or adapters before it is sent for recycling. Plugs and adapters are a totally separate grade and your cable may be downgraded if these are still attached.

Step 2. The cable is shredded or stripped

Once graded, the cable is shredded or stripped. Cable stripping would be done on one of our eight in house cable stripping machines. This process will remove any external layers including lead, sheathing and plastic. Here the cable can be stripped down to bare copper, a grade we call Dry Bright Wire. Using our high tech machinery, this can be done in minutes making the process quite simple. Alternatively shredding is used to reduce the size and remove steel from steel armoured cable.

Step 3. The core of the cable is granulated

Next, the core of the cable is granulated. This process removes any remaining steel or plastic with the use of an integrated magnet, this leaves the copper in it purest form.

Step 4. Any excess metal is removed from the residue

To ensure that no part of the cable core is wasted, any remaining plastic residue left over from the granulation process is processed further to separate any metal that has been left over. This is not only to ensure that there is no waste, but also to ensure that the plastic is not contaminated when it is re-used.

Cable granulation is an important part of ensuring that nothing valuable is ever wasted. Most materials in the world can be broken down and made into something else, so that will give you something to think about when you throw that old phone charger away!