Magnetic segregation, also known as magnetic separation, is the process of separating one magnetically susceptible metal from another with the use of a magnetic force. It is an effective and cheap method used to recover magnetic metals from scrap.

What metals can be recovered using magnetic segregation?

We can recover a variety of re-usable ferrous metals by using the magnetic segregation process such as cast iron and stainless steel. As we use different levels of magnetic strength for the process, any metal that is even slightly magnetically susceptible can be recovered. Most of the ferrous metals that we receive come from steel beams, used cars and household appliances.

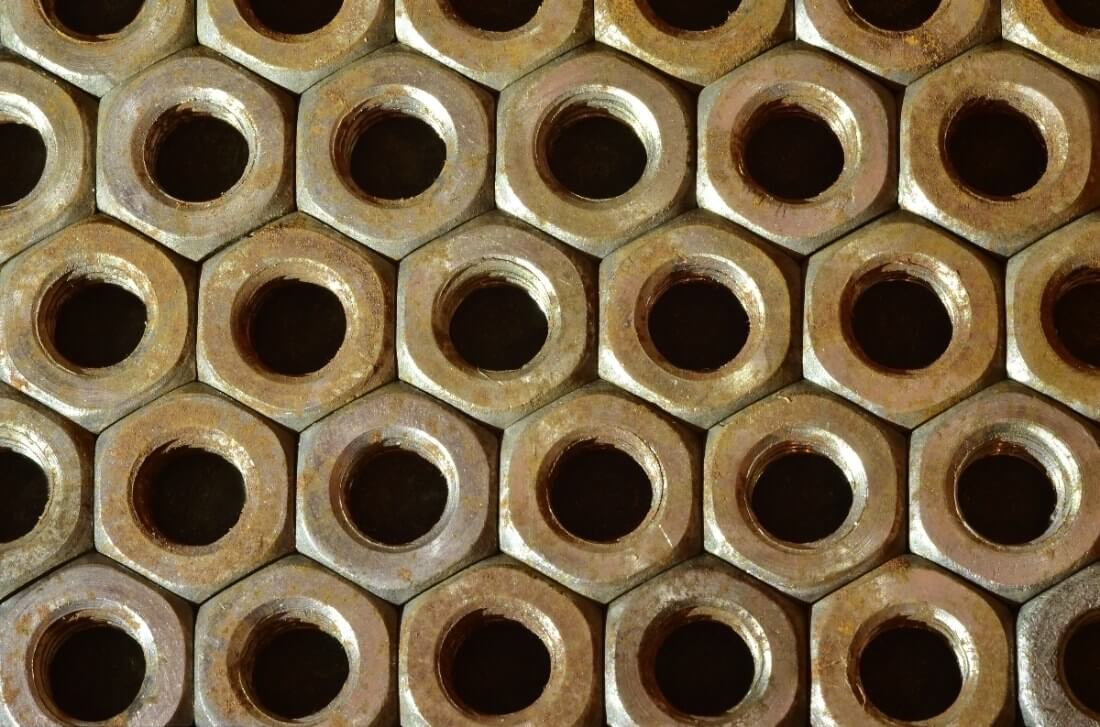

What do we use for the process? The equipment that is used for the magnetic segregation process is dependant on what magnetic field strength is needed to extract the recyclable metal. We can also use machines that will allow us to separate a variety of particle sizes. These can range from large and lumpy fragments to microscopic particles that cannot be seen with the naked eye.

Some interesting facts about magnetic segregation and recycling!

• The first magnetic separator machine was invented by John Price Wetherill and was used to extract steel from a mine in Tasmania.

• Carbon dioxide emissions are reduced by 58% by recycling magnetic materials.

• 75% less energy is used when recycling steel compared to when steel is created using raw materials. This is enough energy to power over 17 million homes!

• The non-ferrous metal aluminium is often recycled, however – if all of the aluminium cans in the UK were recycled, we would need fourteen million fewer dustbins.

• If all of the aluminium cans that were recycled last year were placed in a line, the line could wrap around the world 30 times!

If you would like some more information on the magnetic segregation process or on why recycling metals is so important, or would like to use our services, then give us a call on 0161 790 5105.